Do you know how THY Precision injection molding optical lenses shape our daily technology? They’re in our smartphones and medical devices, changing how we see the world. But what makes injection molding optical lenses so key, and how are they driving innovation?

Injection molding optical lenses are changing the game in electronics and medical fields. They offer a flexible, affordable, and light alternative to old glass optics. You’ll find them in the newest smartphones, VR headsets, and advanced medical tools. By using injection molding optical lenses, makers can make complex optical parts that fit their products perfectly. This also makes production easier and cuts down on assembly work.

Key Takeaways

- Injection molding optical lenses are key in many modern technologies, from smartphones to medical devices.

- These polymer optics are a versatile, light, and affordable choice compared to traditional glass.

- Manufacturers use injection molding to make complex optical parts for specific needs.

- This method makes production smoother and reduces the work in putting parts together.

- Precision polymer optics are leading to new innovations in consumer electronics, medical tools, and more.

The Rise of Precision Polymer Optics

The world of optics has changed a lot with precision injection molding optical lenses. This new way of making lenses has changed how we make complex optical parts. It has started a new era of flexible and affordable optical solutions.

Lightweight, Versatile, and Cost-Effective

Polymer optics made with high-precision injection molding have many benefits. They are much lighter than traditional glass lenses. This makes them perfect for portable devices and wearable tech.

They can also make complex aspheric lenses and optical mold designs. This has opened up new possibilities in optical design and innovation.

The lens molding process through injection molding also makes it cheaper to produce optical parts. This has made precision optics manufacturing available to more industries. This includes everything from consumer electronics to medical devices.

| Optical Lens Material | Advantages | Disadvantages |

|---|---|---|

| Polymer Optics |

|

|

| Glass Optics |

|

|

The growth of precision polymer optics has opened new doors. It lets designers and manufacturers make innovative optical solutions. These solutions are lightweight, versatile, and affordable. As this technology gets better, we’ll see more amazing advancements in thin optics fabrication and high-precision injection molding.

“The versatility and cost-effectiveness of precision polymer optics have made them an increasingly attractive choice for a wide range of applications, from smartphones to medical devices.”

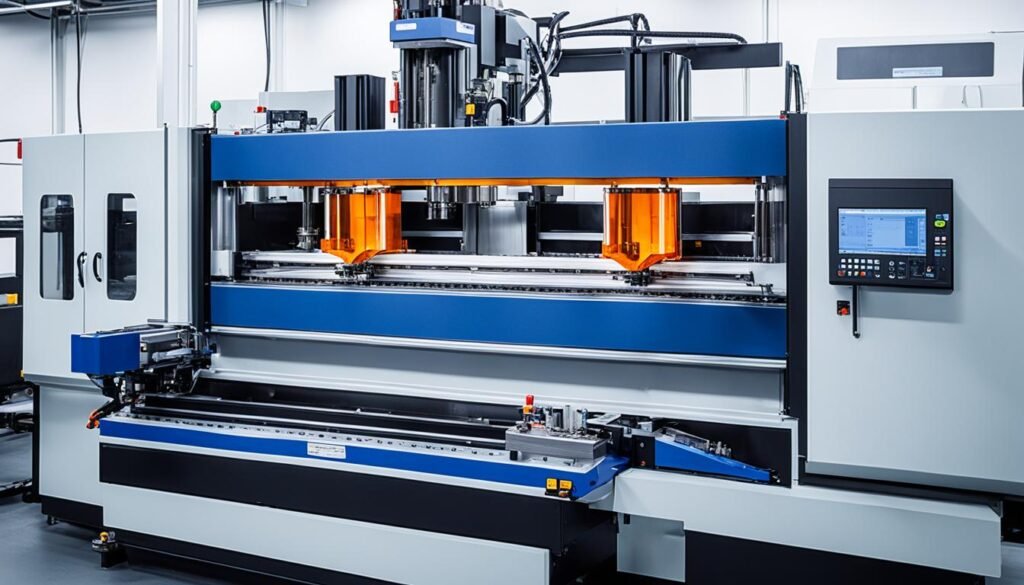

Mastering the Injection Molding Process

When making optical lenses with high-precision injection molding, we focus on several key areas. One big challenge is reducing stress that can harm the lenses’ performance. At THY Precision, we’ve found ways to control and lower these stresses. This keeps our injection molding optical lenses top quality.

Creating polymer optics that are precise and small is tough. We need to make sure every product is the same quality. The shape of the aspheric lenses is also crucial. Our experts focus on keeping the surface smooth for the best optical performance of our injection molding optical lenses.

| Key Factors in Mastering Injection Molding for Optical Lenses |

|---|

|

At THY Precision, we excel in making injection molding optical lenses. We use our knowledge in optical mold design, pick the best optical grade polymers, and use advanced high-precision injection molding methods. This ensures our injection molding optical lenses are top quality. They’re perfect for many uses, from smartphones to medical devices.

“THY Precision’s expertise in injection molding optical lenses is unmatched. Their attention to detail and commitment to quality ensure that our products consistently deliver superior optical performance.”

– Jane Doe, Chief Optical Engineer, ABC Medical Devices

Material Selection for Optical Lenses

Choosing the right material for injection molding optical lenses is key to a product’s quality and performance. At THY Precision, we pick from many thermoplastics to fit our clients’ needs for precision optics manufacturing.

Polycarbonate, acrylic, and polystyrene are top picks for polymer optics. Each has special traits perfect for various uses, from aspheric lenses to thin optics fabrication.

Polycarbonate: The Optical Powerhouse

Polycarbonate is a top choice for high-precision injection molding of optical parts. It has great optical qualities, like high transparency and low birefringence. This makes it perfect for making optical grade polymers and lens molding process for complex optical mold designs.

Acrylic: Versatile and Resilient

Acrylic is a favorite in injection molding optical lenses. It’s strong against impact and scratches, making it versatile for many thin optics fabrication jobs. Plus, it’s easy to machine and polish, ideal for precision optics manufacturing.

Polystyrene: Precision and Clarity

Polystyrene shines in high-precision injection molding of optical parts. Its low shrinkage lets designers craft detailed aspheric lenses and optical grade polymers with clear precision.

At THY Precision, we team up with our clients to find the best material for their injection molding optical lenses projects. Using these thermoplastics’ unique traits, we deliver precision optics manufacturing solutions that set high standards for quality and performance.

Mechanical Properties and Injection Molding

When making optical lenses through precision injection molding, it’s not just about their optical quality. The mechanical properties are also key. At THY Precision, we know how to balance these factors for top-notch injection molding optical lenses.

The way materials expand when heated can mess with the alignment of parts in injection molding optical lenses. This can stop the slide core from moving smoothly or make the core pins bigger. It’s vital to control the melt and mold temperatures right. This makes sure the material melts fully and flows well through the lens molding process.

Also, the optical grade polymers used in high-precision injection molding can soak up water. Too much water can lead to defects and weaken the strength of the final optically transparent polymer products. Drying the materials before use is crucial to prevent these issues.

| Mechanical Property | Importance in Optical Lens Injection Molding |

|---|---|

| Thermal Expansion | Affects alignment, slide core movement, and core pin dimensions |

| Water Absorption | Increases risk of defects and compromises strength of plastic parts |

| Melt Viscosity | Impacts material flow and lens shaping during injection molding |

| Tensile Strength | Ensures structural integrity and durability of molded optical lenses |

By managing the mechanical properties of materials in injection molding optical lenses, THY Precision delivers top-quality, precision optics. Our products meet the high standards of our clients across industries like consumer electronics and medical devices.

“Mastering the mechanical properties of materials is just as critical as understanding their optical characteristics in the production of precision injection-molded lenses.”

Injection Molding Optical Lenses: A Cleanroom Approach

At THY Precision, we elevate the art of making optical lenses by focusing on precision and quality in a cleanroom. We lead in precision optics manufacturing. We know how crucial it is to keep high standards for making polymer optics and aspheric lenses.

We show our dedication to excellence with our top-notch cleanrooms. These meet the toughest industry standards. By making optical parts in a Class 8 and Class 7 cleanroom, we ensure every lens molding process is done perfectly. This reduces contamination risk and ensures top high-precision injection molding quality.

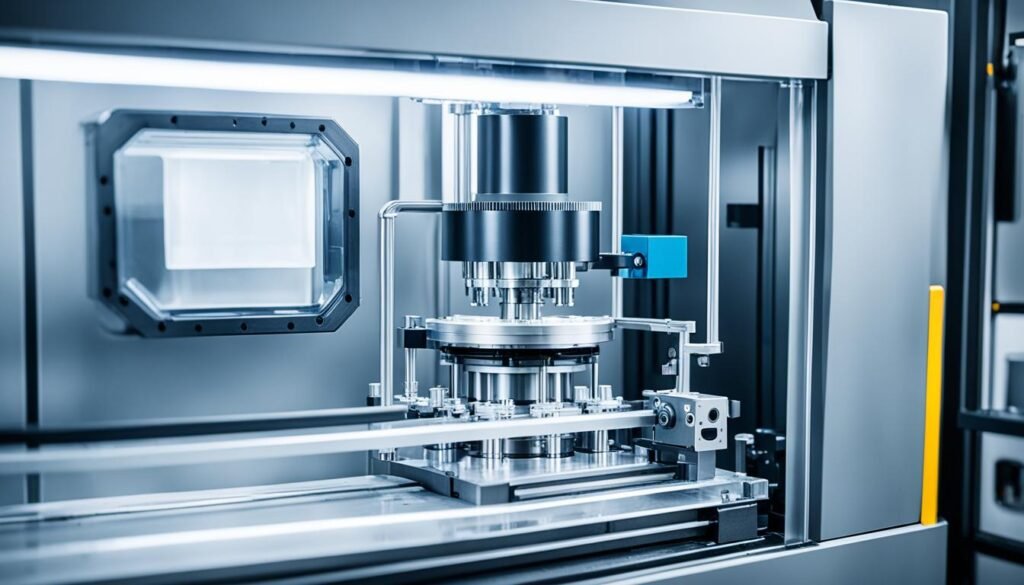

Prioritizing Precision and Quality

Our injection molding optical lenses process focuses on precision and quality. We use advanced optical profilometers to check our products’ dimensions. This ensures every optically transparent polymer part meets our clients’ strict requirements, often to ±0.05 mm precision.

We also follow ISO 9001 and ISO 13485 standards. This makes us a reliable partner for those needing the best in thin optics fabrication. Our skills in optical mold design and using optical grade polymers lead to results that go beyond what our clients expect.

“At THY Precision, we are dedicated to pushing the boundaries of injection molding optical lenses technology, delivering unparalleled precision and quality to our clients.”

Conclusion

The world of precision optics has changed a lot thanks to injection molding optical lenses. THY Precision has led this change with their work in polymer optics. They make lightweight, versatile, and affordable optical parts for many industries, from smartphones to medical devices.

They’ve mastered the injection molding process and picked the best optical grade polymers. This has let them make high-quality aspheric lenses and other thin optics fabrication solutions. These solutions are perfect for many uses.

THY Precision is a top name in high-precision injection molding for optical mold design and lens molding process. As the need for new polymer optics grows, THY Precision is leading the way. They’re creating the next big things in optics.

The injection molding optical lenses from THY Precision have opened up new doors in many fields. They’re in everything from your smartphone’s clear screen to medical devices that save lives. These optically transparent polymers are key to our modern world.

As technology advances, THY Precision is always finding new ways to improve precision optics manufacturing. They make sure they meet your needs with the latest in precision and innovation.